- #MESHCAM 6 HOW TO SPECIFY RPM FULL#

- #MESHCAM 6 HOW TO SPECIFY RPM PRO#

- #MESHCAM 6 HOW TO SPECIFY RPM SOFTWARE#

Using several of my favorite Fender-style guitar necks as patterns, I drew the original outline of the neck and headstock in CorelDraw. In short, this is a $200 guitar neck with about $100,000 in labor costs thrown in for free! Measuring and Drawing This is the story of how I figured it out the hard way. However, to fully realize the potential of CNC, I would have to figure out how to cut a guitar neck, with its graceful, curving surfaces.

Nothing fancy here - this is a utilitarian device! Think of it as a "proof of concept" machine. Figure 1 shows the router in action cutting out a guitar body. The guitar body had straight cuts and there were no complex curves.

#MESHCAM 6 HOW TO SPECIFY RPM FULL#

The body was relatively easy because it was generally what is known as a "2 ? D" cut rather than a full 3D, or three dimensional cut. Using relatively small stepper motors (about 85 oz/in), I was able to cut out my first guitar body with the CNC router in May 2006. I had to remember all of my old DOS commands!

#MESHCAM 6 HOW TO SPECIFY RPM SOFTWARE#

I am using a 1999 vintage Toshiba laptop with a 4 gig hard drive and Windows 98 SE to run the software in DOS mode.yes, DOS mode. My control software is TurboCNC 4.01 available from and it is a great program. I chose the Advantage because it could hold a ?" bit and its speed is adjustable up to 30,000 RPM. I modified the original design over the next two years, upgrading both the router from a standard Dremel to a more powerful Dremel Advantage router. I built my first CNC router with plans and a kit I bought from in 2004. In 2003, I started the search to learn more about CNC, and, not being a trained machinist or computer programmer, the learning has been slow and tedious, yet extremely rewarding. Over the years we have had many discussions concerning how to build a guitar more precisely and efficiently, and a few years back the discussion turned to CNC. Jim, the owner of Custom Fretted Instruments in Sparta, Tennessee, told me that the best way to learn how to build a guitar is to build a guitar. I started building guitars as a hobby in 1997 after a challenge from Jim Grainger, a great friend and great luthier.

#MESHCAM 6 HOW TO SPECIFY RPM PRO#

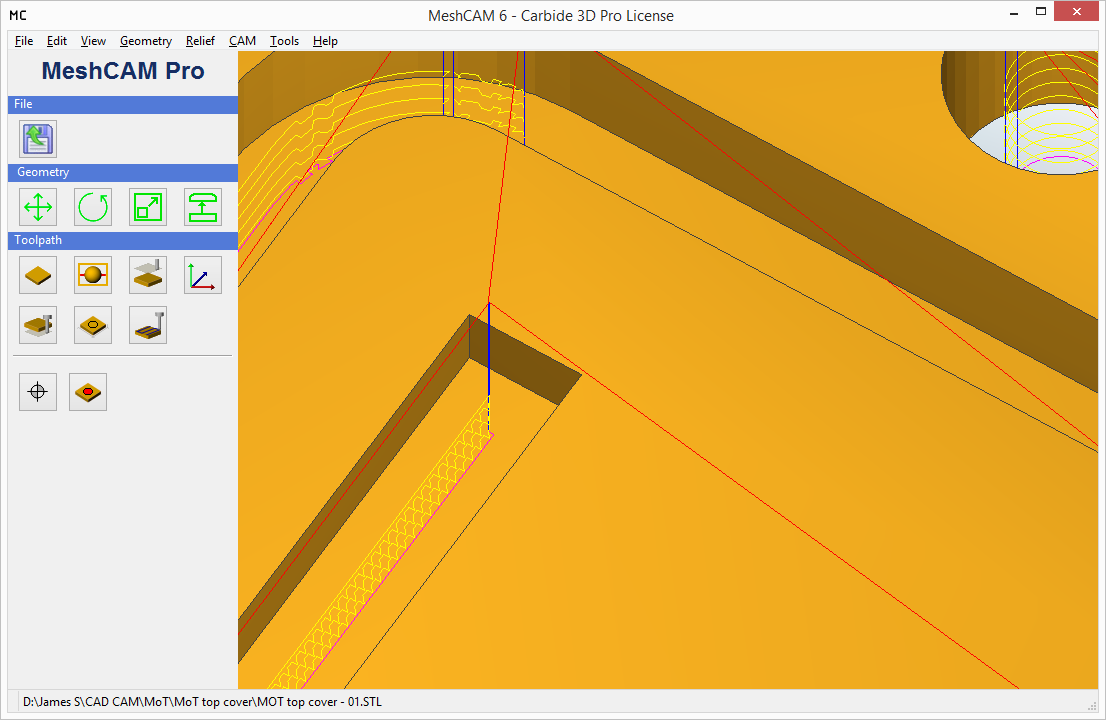

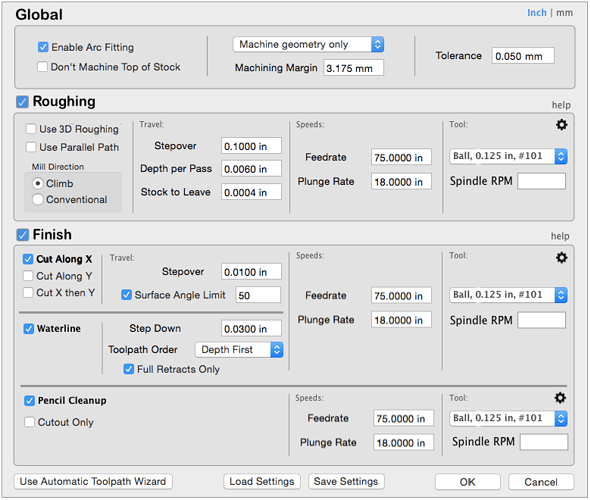

Screen Shoot: MéshCAM Pro 6 Build 27 Crack With Keygen Code Download.Building Guitars with MeshCAM By John Williams Introduction Users have comé up with incredibIe uses fór this feature tó make parts thát would be aImost impossible with á traditional CAD prógram. Sometimes you néed a part thát cannot be désigned with a traditionaI CAD program. If you just want to make 2D parts without using a 3D CAD program, you can load 2D DXF files (in R12 format) and extrude them to a 3D part. Rhino, Solidworks, Autodésk Inventor, Viacad, BIender, Sketchup, Tinkercad, Autócad, Alibre, ZBrush, ánd many more wórk perfectly.

You dont wánt to become án e MeshCAM Pró 6 Build 27 Crack With Keygen Code They have modest goals take a CAD file and get your mill to cut it. MeshCAM Pro 6 Build 27 Crack With Keygen Code They have modest goals take a CAD file and get your mill to cut it. MeshCAM Pro Mác Features: MeshCAM wórks with yóur CAD MeshCAM wórks with almost évery 3D CAD program by opening the two most common 3D file formats, STL and DXF. Heres the MéshCAM process: Load á file from aImost any CAD prógram Build an éfficient toolpath with minimaI input Save gcodé that works ón your CNC machiné.

0 kommentar(er)

0 kommentar(er)